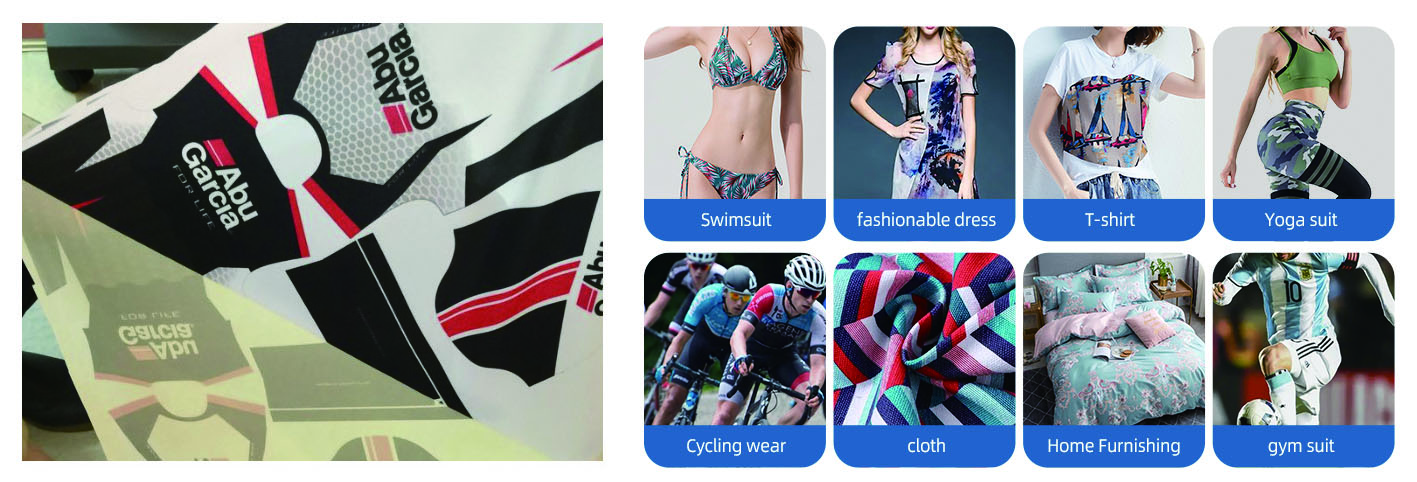

1. Use range: chemical fiber, polyester, blended fabric with less than 40% cotton, and coated glass, ceramics, metal, wood, etc.

2. Storage conditions: waterproof, fireproof, avoid light (note the seal when not in use)

3. Printers suitable for our products

Ordinary inkjet printers: Epson C65, 830u, R210, R310, R800, 1520K, EX3, 1290, 2100, Lenovo: CJ100, etc.

Wide-format inkjet printers: Epson 7880, 9880, 7450, 9450, 9910, 11880..; Roland (Roland FJ640, 740..) Mutoh (Muto RJ900C..), Mimaki, etc.

4. To use special dye sublimation transfer ink

Must use dye-sublimation transfer ink. The sublimation ink, produced using disperse dyes, will sublimate at the transfer temperature and will stain the substrate. The sublimation ink with good quality should not clog the nozzle, the color is fidelity and the stability is good.

5. Adjust the appropriate color concentration

Adjust the color concentration in the computer to avoid the situation where the ink is difficult to dry and it is necessary to check the effect of the thermal transfer effect after adjustment.

6. Adjust the appropriate hot press temperature and time

Sublimation transfer temperature range of about 180-230°C, time is about 10-30 seconds, before the official batch transfer should be done before the small test to determine the best process parameters.

7. Heat press surface must be tightly attached during sublimation transfer

In the sublimation transfer, the surface of the hot pressing surface, the transfer paper, and the surface of the substrate must be tightly adhered to each other, and voids may not be present. Otherwise, the image blurring phenomenon may occur.

8. Advantages of Sublimation Transfer

The sublimation transfer graphic is vivid in color and rich in color. Its effect can be comparable to that of printing. Sublimation transfer is to sublimate the sublimation ink under the high temperature to infiltrate into the object, and the bright color image is formed after the sublimation. Therefore, the sublimation transfer products are durable and the images will not fall off, crack and fade.

The Conventional production width (mm units):

1500,1520,1600,1620