Heat Transfer Film

Heat transfer film products, this series of products are coated with BOPET base material and multiple precision coatings, and are divided into two types according to the peeling method: cold peeling, hot peeling, hot & cold peeling. According to the product effect, it is divided into: matte, bright, and flat. According to the product use, it is divided into screen printing film, traditional ink heat transfer film, laser film, etc. Various combinations form different product effects and uses.

Product Features

1. The heat transfer temperature of this product is between 130-160 ℃. After the transfer printing, it has a matte effect.

2. Since the back-coated anti-adhesive layer of double-side film, it can prevent long-distance transportation and pressure-induced adhesion and heat scrapping of the product, and can save the cost of adding release paper and transportation costs. It is precision-processed after multiple coatings. The ink layer absorbs quickly and the surface High flatness, can reach 175-210 line screen printing, no matter fine pattern or color block printing can achieve ideal effect.

3. Coating with high-quality substrate, with environmental protection, anti-aging, weather resistance, excellent strength

Excellent washing resistance, bending and other properties.

4. High-precision coating equipment is used to produce and synthesize, with stable release force and guaranteed quality.

5. This product has a wide range of uses, such as the production of traditional ink heat transfer, the production of silk screen washing water labels.

Application

Precautions

1. Keep the substrate clean and tidy before transfer printing;

2. Try to avoid contact with sharp objects during printing and production, so as not to scratch and affect the effect;

3. Try to avoid contact with high temperature objects during printing and production;

4. Handle with care during the color printing process to prevent the color printing pattern from being scratched;

5. After screen printing, the baking temperature should be between 50°C and 65°C to prevent slight deformation of the film due to excessive temperature and inaccurate registration.

6. Cut off the other blank parts of the image before transferring, leaving a border of 2mm;

7. The temperature of the heat press machine reaches the set temperature of 130°C to 160°C, and the pressing time is 8-12 seconds; the pressure is about 0.3MPa;

8. When the machine time is up, lift or remove the heating plate of the heat press machine, and be sure to tear off the film on it immediately;

9. Under normal circumstances, the opening side of the package is the printing side;

10. This material is an anti-sticking material, but a piece of anti-sticking paper should be added on the upper layer of the finished heat transfer package.

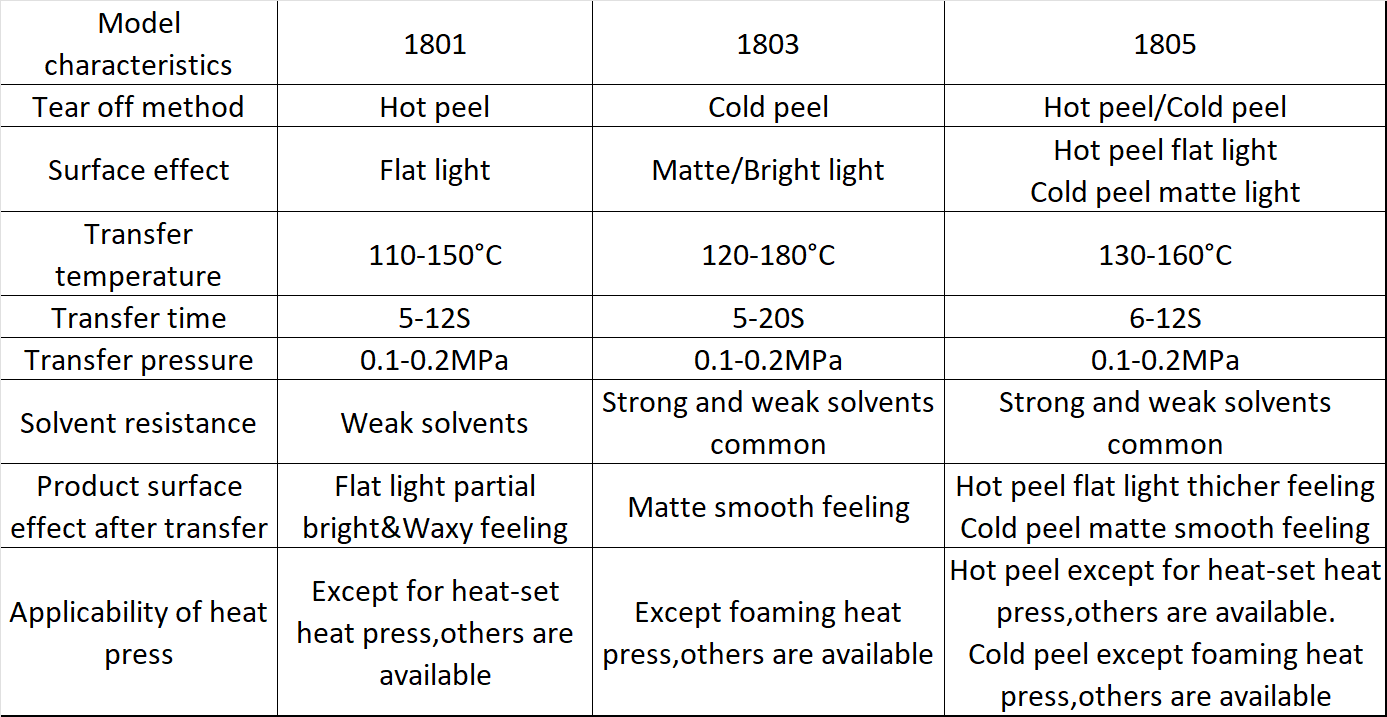

Technical Specifications

1. Main materials: BOPET base material and multiple precision coatings;

2. Hardness: 65A to 90A (can be customized)

3. Thickness: 0.03MM-0.3MM, 50um, 70um, 100um normally, other thicknesses can be customized;

4. Adhesion: 60-150 N/25mm;

5. Operating temperature: 130-160C, operating time: 8-12S;

6. Normal size: 39cm*54cm, 48cm*64cm, 1000/700 sheets per box, other length can be customized, and can be cut into small sizes for customers;

7. Coil length: 50 meters per roll, 100 meters, 200 meters can be customized;

8. Environmental standards: SGS certification: formaldehyde, total lead, phthalates, eight heavy metals, azo, organotin, polycyclic aromatic hydrocarbons